Views: 2 Author: Site Editor Publish Time: 2023-06-25 Origin: Site

Producers of ERW, LSAW, SSAW, and Spiral Steel Piping

The steel pipes industry relies heavily on several key-manufacturing procedures that have been employed on a global scale, such as Electric Resistance Welding (ERW), Longitudinally Submerged Arc Welding (LSAW), and Spiral Submerged Arc Welding (SSAW). Each of these processes brings its own edges to the table, helping companies in the sector cater to myriad demands from the ever-evolving industries. Consequently, the professional companies engaging in these techniques have become an essential presence in the manufacturing landscape.

ERW steel pipes are produced by electric resistance welding, a process that involves applying a welding current to heat the edges of a steel strip or plate. After the edges have been heated, they are forced together to create a seamless connection. These pipes are highly accurate in terms of dimensions and typically used for applications with low to medium-pressure requirements like water supply, piping, and construction.

Manufacturers of LSAW steel pipes leverage the longitudinally submerged arc welding process to create a pipe. Here, a metal plate is initially reshaped into its tubular form before having its sides heated and accompanying flux immersed to secure the welding procedure. An electrical arc is then employed to link the edges, forming a continuous welded joint. Renowned for their superior strength, these pipes are, typically, used as part of oil and gas transportation systems or for structural engineering purpose.

When it comes to SSAW steel pipes production, manufacturers rely on the spiral submerged arc welding technique. This technique is notably similar to the LSAW method, except for one substantial difference: steel strips and plates are formed in a spiral shape prior to welding. This makes the pipe more flexible and therefore perfect for uses that require an element of deformation resistance, such as pipelines used for oil, gas, and water transportation.

Steel pipe producers employ the spiral welding technique to create their pipes. This method involves forming steelplate or strip into a pipe using a continuous helical line. The bordering of the plate is welded together in a spiral seam formation for added sturdiness. These spiral pipes possess extraordinary robustness and resilience, making them an excellent choice for tumultuous projects such as oil and gas transportation, water treatment projects, and off-shore platforms.

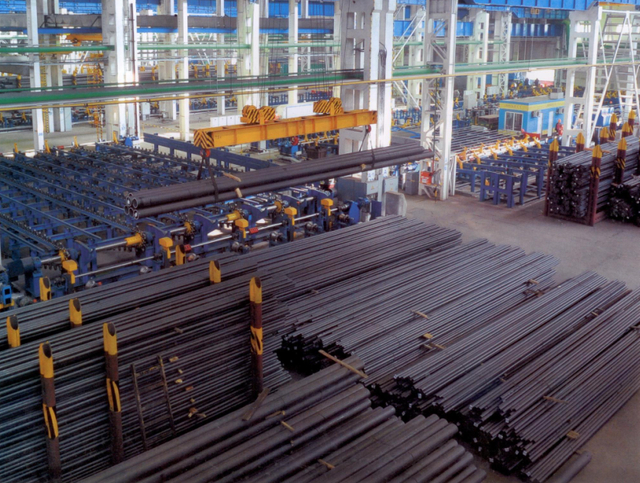

Manufacturers that specialize in ERW, LSAW, SSAW, and spiral steel pipes keep everything to the highest standards of quality. Raw materials undergo thorough inspection, welding parameters are monitored meticulously and various tests are carried out to guarantee compliance with international quality protocols. The companies also invest in top-of-the-line equipment and technology to help increase productivity and efficiency.

As sectors around the world expand, the craving for Electric Resistance Welding (ERW), Longitudinal Submerged Arc Welding (LSAW), Spiral Submerged Arc Welding (SSAW) and Spiral steel pipes intensifies. To cater to the increasing demand, a slew of manufacturers have mushroomed; yet, selecting dependable furnishers with an established history of providing top-notch pipes that aligns with one's specific requirements is vital.

To meet all manner of industry demands, ERW, LSAW, SSAW and spiral steel pipe manufacturers are an indispensable social partner. Through their unique advantages, these manufacturers can produce pipes suitable for any application, whether it be plumbing, structural engineering, oil and gas transfer or something else entirely. To ensure their products are of the utmost quality and international standards are maintained, these specialists incorporate strict quality control protocols combined with cutting-edge technology. Customers can be sure that the supplies sought from these companies will be dependable and long-lasting.