Views: 0 Author: Site Editor Publish Time: 2023-06-28 Origin: Site

Encouraging Sustainable Progress Through Low Carbon SSAW Steel Pipe Manufacturing.

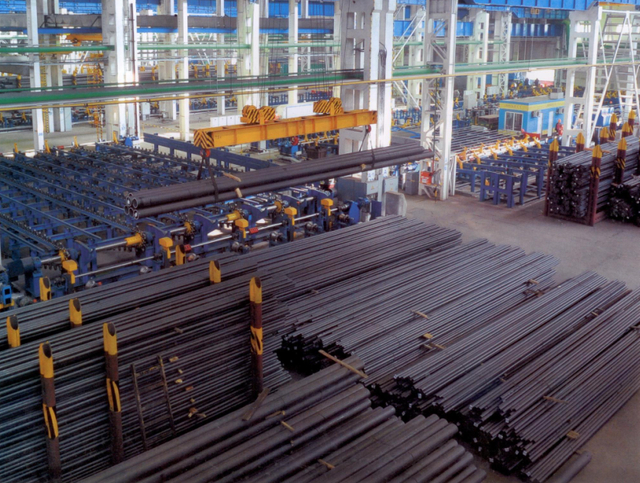

The steel pipe manufacturing sector has made marked progress towards a more environmentally-conscious and sustainable industry in recent years. Low carbon SSAW steel pipe factories, in particular, stand out for their commitment to delivering top-notch steel pipes without compromising on their carbon output.

Manufacturing steel pipes with minimal emissions can now be done thanks to advanced technology employed by low carbon SSAW steel pipe factories. Utilizing low-carbon materials as well as utilizing cutting-edge production tools, these factories are spearheading the way towards a greener, more sustainable future. With these measures in place, high quality steel pipes can be produced with fewer carbon emissions to meet stringent standards.

SSAW steel pipe factories strive to reduce their environmental impact through the utilization of low-carbon materials. Low-carbon SSAW steel pipes are produced by submerging an arc welding technique. This ensures that the carbon content is lower than the traditional manufacturing process, thereby giving these productions a more sustainable flair.

To help reduce their carbon footprint, low carbon SSAW steel pipe factories are putting in place various energy-saving processes. From high-pressure water descaling machines to optimise energy consumption while producing to advanced recycling methods for the reuse of waste materials, these factories are taking measures to both minimise pollution and preserve resources.

Low carbon SSAW steel pipe factories are devoted to sustainability, taking their efforts beyond the manufacturing stage. Optimizing delivery routes and using eco-friendly vehicles for transportation are the tactics employed to preserve fuel, reducing greenhouse gas emissions. These factories are doing their part to ensure a smaller environmental footprint through the entire supply chain.

The great strides taken by SSAW steel pipe factories towards sustainable development have been recognized and duly rewarded. Their investment in eco-friendly processes has earned them such important acknowledgements as ISO 14001:2015 certification - a validation of their commitment to reduce their carbon footprint and foster sustainability. This is something that customers all over the world are starting to value more, and manufacturers are cheering the growing demand for their eco-savvy goods.

To create a more sustainable economy and environment, low carbon SSAW steel pipe factories are paving the way forward. By using low-carbon materials, employing energy-saving initiatives and enacting environmentally friendly transportation methods, these factories can lessen their carbon footprint whilst still meeting consumer needs. Continuously increasing demand for eco-friendly production means these factories are in a prime position to offer sustainable solutions and a brighter future.