Views: 0 Author: Site Editor Publish Time: 2023-06-14 Origin: Site

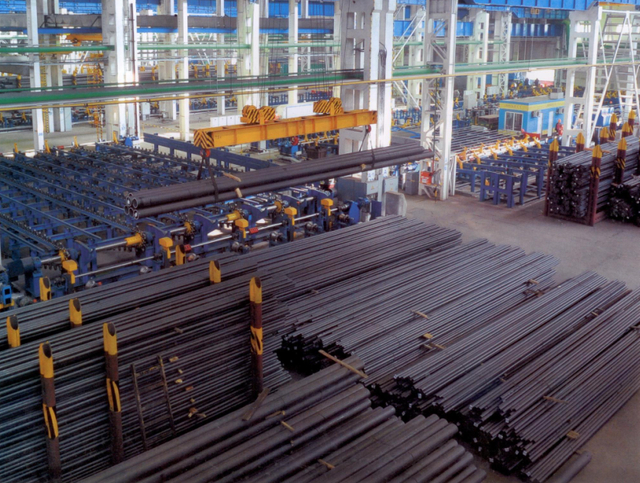

A Revolutionizing Step Forward: LSAW Spiral Steel Pipes in the Steel Sector.

The steel industry has seen an unprecedented leap forward with the inception of LSAW spiral steel pipes. Boasting superior strength, endurance, and versatility over traditional pipes, these pipes are revolutionizing the way the industry uses steel. In this piece, we’ll take a closer look at the wonders of the modern-day LSAW pipe and its numerous advantages in industrial scenarios.

Spiral steel pipes known as LSAW (Longitudinal Submerged Arc Welding) are an adept solution for a range of piping needs. They are formed by bending and shaping a steel strip into a spiral form, followed by a careful welding of adjoining edges with a submerged arc welding technique. This precise manufacturing process delivers moisture-resistant and resilient pipes with consistent welds for superior results.

LSAW spiral steel pipes offer an array of impressive benefits that make them an indispensable part of countless industries. Structurally-speaking, these pipes boast exceptional strength and flexibility when withstanding internal and external pressure - making them the ideal choice for transporting various fluids, like oil and gas, securely over long distances. Their unique spiral shape is the core element in their dependability for reliable transportation.

Spiral steel pipes manufactured utilizing the LSAW process demonstrate high resistance to corrosion. Built to endure difficult conditions, including moisture, harsh chemicals, and extreme temperatures, these pipes are suitable for many applications, such as water treatment, chemical processing, and oil & gas industry operations.

The cost-effectiveness of Longitudinal Submerged-Arc Welded (LSAW) spiral steel pipes is an important advantage. Offering a lower cost than alternative steel pipes, these products have an efficient manufacturing process that reduces time and labor expenses as well as lasting durability and corrosion protection which minimizes the need for replacements. Therefore, making them a cost-effective choice in the long haul.

LSAW spiral steel pipes are becoming increasingly sought after due to their ability to be custom-fitted for many different uses. With a range of sizes and diameters, they are the ideal choice for a variety of projects, from construction to piping for fluids and gasses. Their versatility ensures that your particular project will have a perfectly tailored solution that meets your exact needs.

The distinctive capability of these pipes lies in their malleability, allowing for custom shapes and forms to be created. Thus, designers, architects and engineers are presented with an abundance of opportunities to fabricate and modify them to bring forth creative and environmentally friendly designs.

LSAW spiral steel pipes have been a real game-changer for the industrial sector; with their highly durable and resistant build, corrosion-free edges, cost-efficiency, and flexibility aplenty – these pipes are truly unrivaled. As the need for reliable and dependable steel pipes continues to increase, LSAW spiral steel pipes remain the go-to choice for experts in an array of engineering projects worldwide. This has enabled major projects to be successfully completed with great efficiency, further cementing LSAW spiral steel pipes' impressive reputation.