Views: 0 Author: Site Editor Publish Time: 2023-06-19 Origin: Site

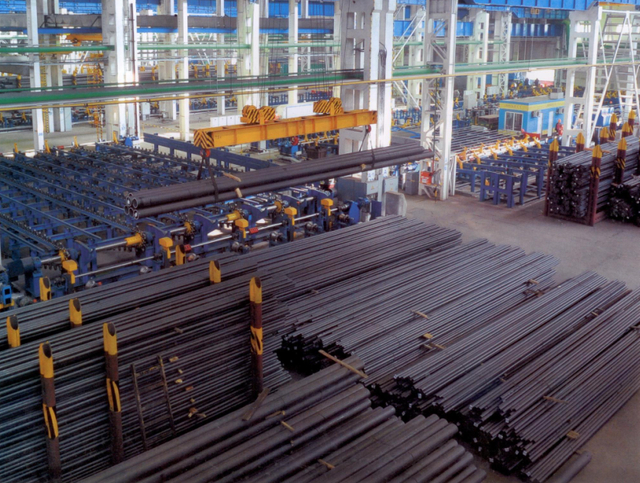

OEM LSAW welded steel pipe provides reliable solutions for a range of industries. From process piping to tube fabrication, it's an effective approach for both large and small applications. With strong welds and durable material, you can trust that your projects will be completed on time and on budget. So don't hesitate to turn to this resource for reliable infrastructure solutions.

LSAW (Longitudinal Submerged Arc Welded) pipes boast the ideal combination of strength, durability, and versatility which has prompted their growing popularity amongst many industries in need of robust and reliable pipe solutions. OEM (Original Equipment Manufacturer) LSAW pipes are especially favored due to their ability to be employed in a variety of infrastructure projects from transportation networks to oil and gas pipelines and water supply systems.

Steel Longitudinal Submerged Arc Welding (LSAW) technology is the process of fusing steel plates to form a cylindrical shape and yields a uniformly thick pipe with outstanding mechanical properties. This method of welding provides superior density and sturdiness, making it well-suited for applications that are subject to extreme internal or external pressures.

Custom-made LSAW welded pipes provide the perfect match to a variety of industrial needs. From construction to offshore drilling, water transmission and more, these pipes ensure consistency and reliability, crafted to the exact demands of each client. OEM LSAW welded steel pipes guarantee an optimal solution that surpasses the highest benchmarks.

OEM LSAW welded steel pipes have impressive durability and resistance to corrosive elements, lending them a lengthy service life. Furthermore, their ability to weather extreme situations, coupled with their capacity to endure high pressures, make them ideal for carrying liquids and gasses across different systems.

OEM LSAW welded steel pipes have solidified their place in the oil and gas sector as a reliable and safe alternative. Both offshore and onshore drilling sites employ these pipes to guarantee a secure connection between storage facilities and wells. Carefully crafted to OEM standards, the robust design of these pipes restricts leakage, reducing the probability of pipe breakdowns and improving overall operational effectiveness.

OEM LSAW welded steel pipes are an invaluable asset to the construction industry due to their broad range of applications. From connecting bridges and structures to providing structural support and making a design more reliable, this type of pipe benefits those in the engineering and architecture fields by allowing for more freedom in their creations. Custom notions for specific dimensions are an added feature that instils extra confidence about the structural reliability.

OEM LSAW welded steel pipes offer an optimum material for efficient and sustainable water management. Not only do they boast exceptional corrosion-resistance properties, but also provide dependable pressure handling, meaning they can effectively meet the demands of modern water supply networks. Especially considering the growing concern over global water scarcity, these hardwearing pipes represent a dependable solution for an ever-challenging issue.

OEM LSAW welded steel pipes have become an invaluable asset across numerous industrial contexts, offering bespoke solutions to fit specific requirements. Exceptional strength and durability, coupled with an enviable level of versatility, make these pipes the go-to option for even the most exacting of projects - enabling them to deliver reliable, sustained performance in extreme conditions. As our need for sustainable infrastructure increases, OEM LSAW welded steel pipe will no doubt remain a key factor in meeting this demand.