Views: 0 Author: Site Editor Publish Time: 2023-06-14 Origin: Site

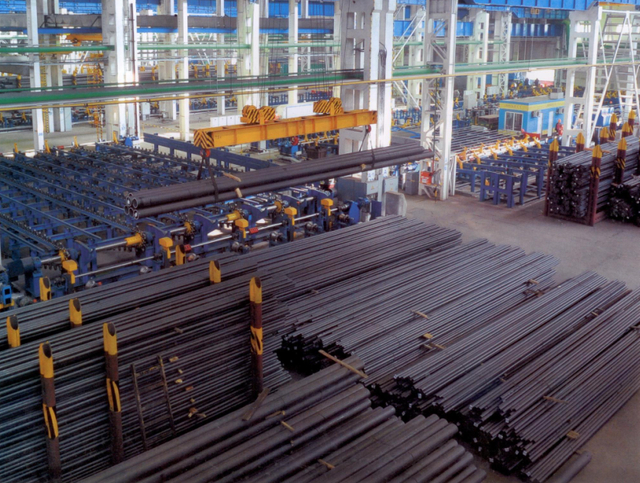

OEM Welded LSAW Steel Pipe: A Dependable Choice for a Range of Industries

When transporting liquids and gases, particularly in the oil & gas, construction, and water treatment industries, having access to dependable pipelines is regularly essential. Amongst the various solutions available, a welded Longitudinal Submerged Arc Welded (LSAW) steel pipe has become an incredibly well-liked choice. We will go into detail about the features and advantages this type of piping can bring to organizations in a number of fields, illustrating why it is so popular.

Forging superior-quality pipes begins with precision welds through Longitudinal Submerged Arc Welding (LSAW), where steel plates are bent then secured together. This welding method ensures impeccable uniformity, accuracy, and consistency, rendering LSAW the perfect choice when seeking a reliable and resilient solution for heavy-duty projects.

OEM welded LSAW steel pipes boast tremendous strength, making them ideal for difficult and demanding applications. They handle heavy loads better, so there's less chance of disaster due to bursting or leakage. Be it for transporting petroleum, natural gas, or even water, these pipes deliver reliable service - a clear advantage over their alternatives.

As industries expand and modernize, their requirements for larger-diameter pipelines also increases. OEM welded Longitudinal Submerged Arc Welding (LSAW) steel pipes are the perfect solution to this requirement. These pipes come in various sizes; ranging from 16 inches to 60 inches wide, being able to accommodate even the most demanding project specifications. With these plentiful options at hand, integration with already existing pipelines or construction of brand new ones can be done without effort. Choosing LSAW pipes enables an easy and convenient solution for larger diameters.

OEM welded LSAW steel pipes boast exceptional resilience to corrosion, thanks to coatings such as epoxy or zinc which shield them from rust. This renders the pipes a longer lifespan, cutting down on costly upkeep and material replacement.

LSAW pipes are designed with an interior that is extremely smooth and free from obstructions. This quality of the pipes allows for a smooth and consistent transfer of liquids or gases - a feature that is particularly beneficial for industries where uninterrupted flow is highly important. Oil refineries and power plants, for example, stand to gain great value from such pipes.

OEM welded LSAW steel pipes have little negative environmental repercussions when compared to other materials. Produced according to the highest quality specifications, these pipes generate virtually no waste during their fabrication process. When current use is depleted, they can be collected and reused as recycled materials; this aids in the pursuit of sustainable solutions and lowers the amount of carbon dioxide released into the atmosphere.

As we move forward, OEM welded LSAW steel pipes have become an increasingly popular solution in different industries for their incomparable strength, impressive large-diameter capacity, impediment to corrosion, sleek inner sealing, and friendliness to our environment. As the dependence on reliable pipeline systems rises, these pipes offer durable and lasting use for transferring liquids and gases. From oil & gas exploration to wastewater treatment plants, these pipes are considered absolutely essential to guarantee the optimal functioning of operations. If industries invest in OEM welded LSAW steel pipes, they can enjoy the advantages of greater efficiency, affordability, and success overall.